Doing it all under one roof

ONE-STOP SHOP FOR RELIABLY GETTING RESULTS

Die casters can provide aggressive timelines on a quote by relying on outside tool shops, engineers, consultants and freelancers. But then you may find out the project is delayed because that shop has their own business plan and priorities. Or that corners are cut, and dirt swept under the rug because having a smooth launch and world-class production quality and reliability is ultimately not the actual goal of everyone involved. When the true launch date is understood to be “the date where your supplier is ready to reliably ship at volume”, a sampling date becomes only one milestone in a journey.

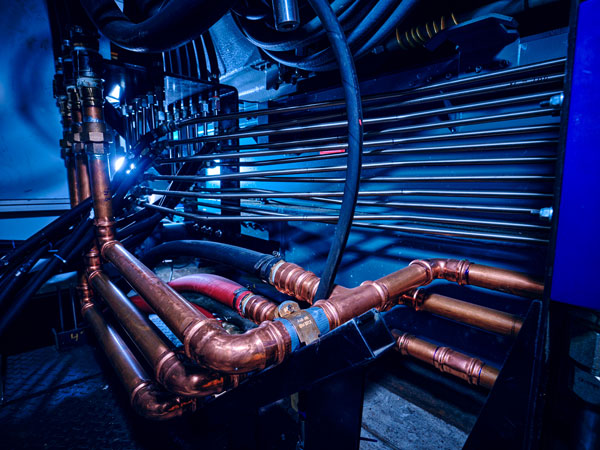

Leak Tight Casting

AMT is not a one-trick pony

Our process expertise allows us to properly understand each project’s features and pick the right solutions out of our engineering toolbox, which is rich with decades of problem solving and innovation. This is why we supply parts as varied as high-volume leak-tight automotive parts, load-bearing and ultra-thin structural components, powertrain components operating at high RPM, chrome-plated mirror-finish castings and more.

Die Casting Manufacturer

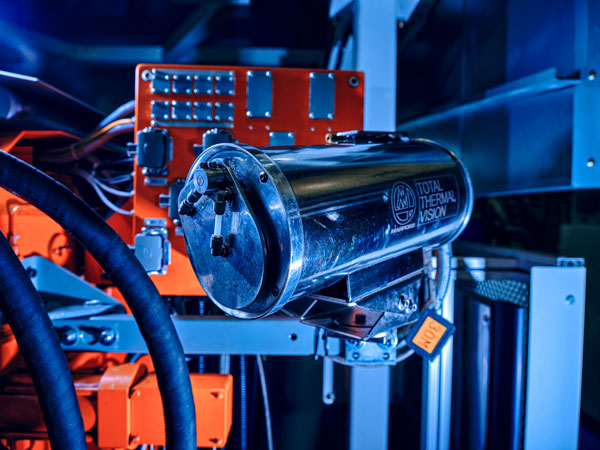

AN AMT PROJECT ENGINEER IS RESPONSIBLE FOR EACH PROGRAM AND ENSURES ALIGNMENT OF YOUR TEAM WITH OURS

Dedicated project engineers

With the help of domain experts, the project engineer oversees the whole project. After program launch, the project engineer remains involved in technical and quality communications, improvement and change management.

- Part design recommendations

- Simulation

- Die design and manufacturing

- Quality planning (including APQP/PPAP activities)

- Process book definition

- Sampling

BETTER AND FASTER, TOGETHER, AS ONE TEAM, UNDER ONE ROOF

Because we can do everything under one roof, we can achieve notable results, faster. We can react quicker, and in a more decisive fashion, to issues and changes. And whenever it makes sense to involve an outside supplier, we can manage them effectively because of our experience in doing the work ourselves.

Because we can do everything under one roof, we can achieve notable results, faster.

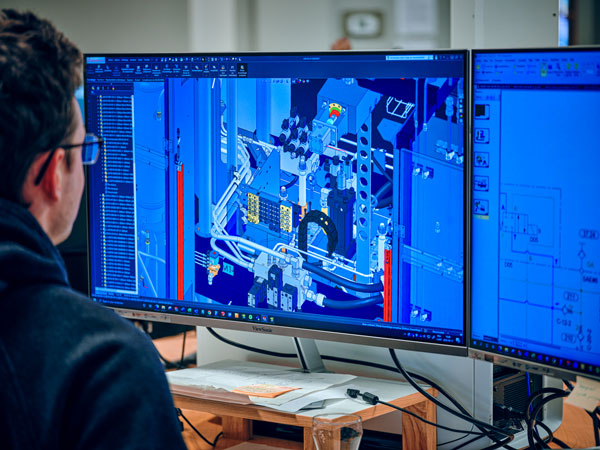

SIMULATION: A TOOL FOR DIE CASTING EXPERTS

Screen captures of simulation results make for good marketing material, as they carry an array of sophistication. We plead guilty, we do it too! Simulation only approximates reality, and its accuracy is highly dependent on how it is used. The quality of the simulation has at least as much to do with the knowledge of the user as with the software itself. As with all things numerical, the saying is true: garbage in, garbage out. And you always need an expert to interpret the results, as simulation software can reveal potential issues, but can also send false alarms or downplay important aspects.

Our simulation methods have become representative enough of reality that we not only use them as a tool to screen initial die designs and troubleshoot production issues, but also have developed ways to feed actual production data back into the simulation to better match reality, and virtually test process changes.