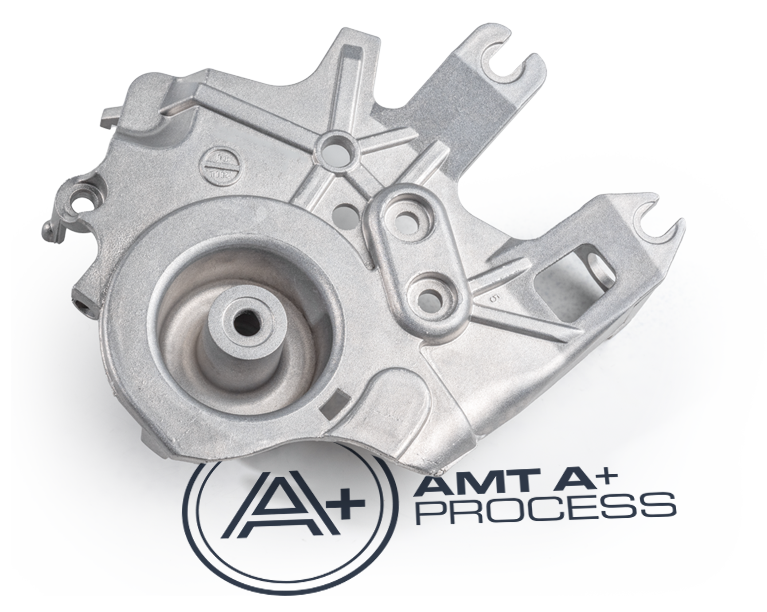

Vacuum Assisted Die Casting

Extreme vacuum, primary alloys and heat treatment for improved mechanical properties, crash-worthiness and weldability.

AMT’s A+ process includes an extreme vacuum system as well as many advancements that bring cavity pressure at a level so low that the resulting castings can reliably undergo heat treatment. Primary alloys optimized for mechanical properties can therefore be used. Typical applications include very thin structural components and weldable parts.

Die Casting Technology

High integrity die cast parts are not made in (just) a vacuum

While vacuum certainly is necessary to manufacture high-integrity die casting components, there is a lot more at play. AMT has heavily invested to optimize several aspects of dies, equipment and control.

Die Casting Heat Treatment

NADCA Award-winning products

AMT has been shipping heat-treated parts in production for more than 10 years. We believe that innovation and quality are elements that are tightly woven into the AMT culture – see for yourself. The North-American Die Casting Association (NADCA) has chosen AMT as recipient for prestigious “Casting of the year” awards in 2014 and 2018 in the structural component category.