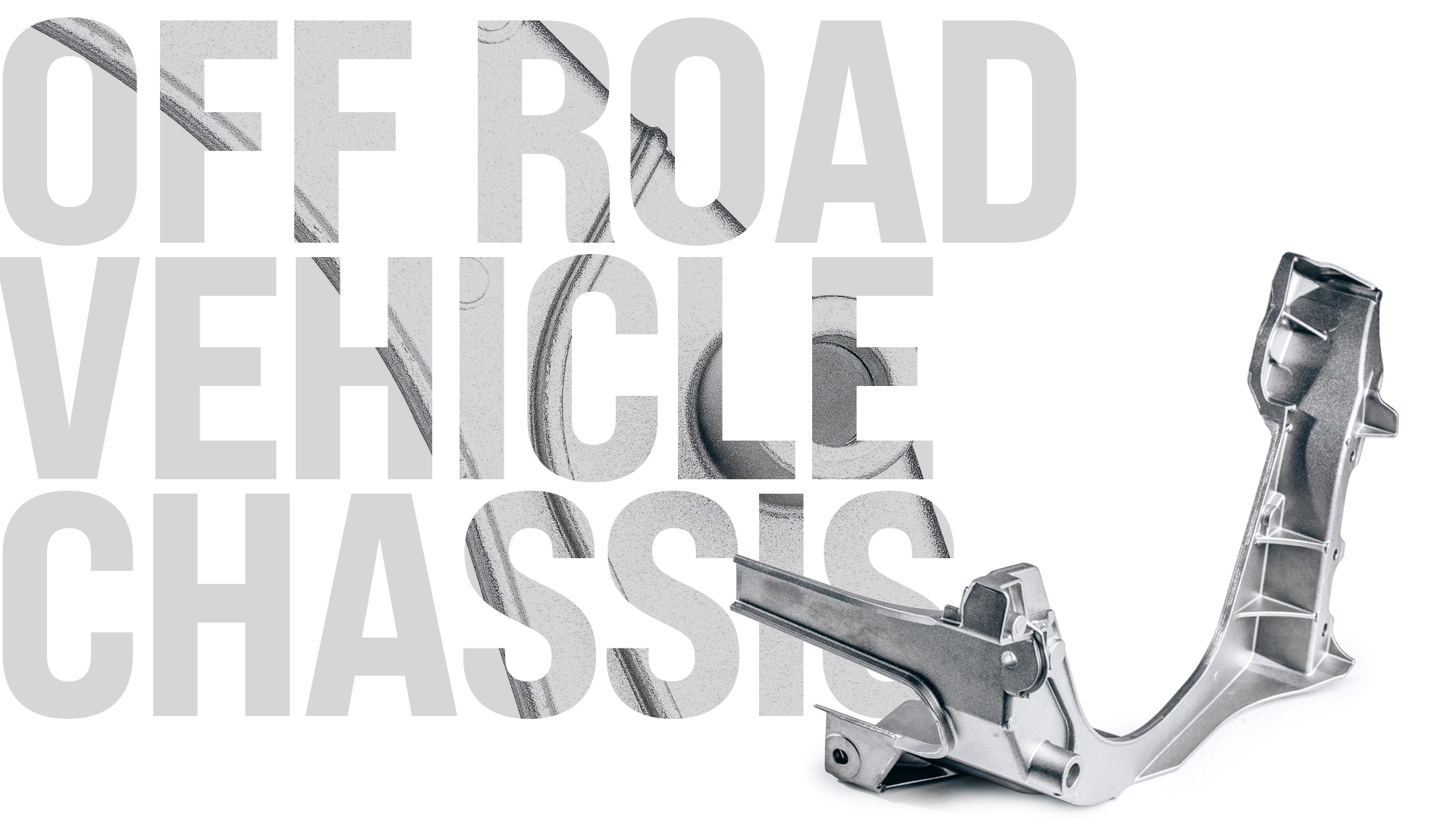

Aluminium high-pressure die casting

Structural die casting engineered for function integration, stiffness-to-weight and assembly simplification.

Alloy: Low iron, primary grade material. Chemical composition custom tuned for customer’s targeted mechanical properties.

Heat-treatment: Single stage heat-treatment designed for minimal distortion.

Weldability: Yes (joining-ready design + controlled distortion strategy)

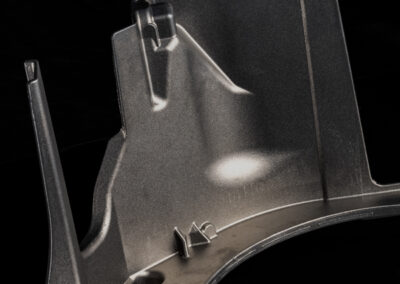

Average wall thickness: 3mm.

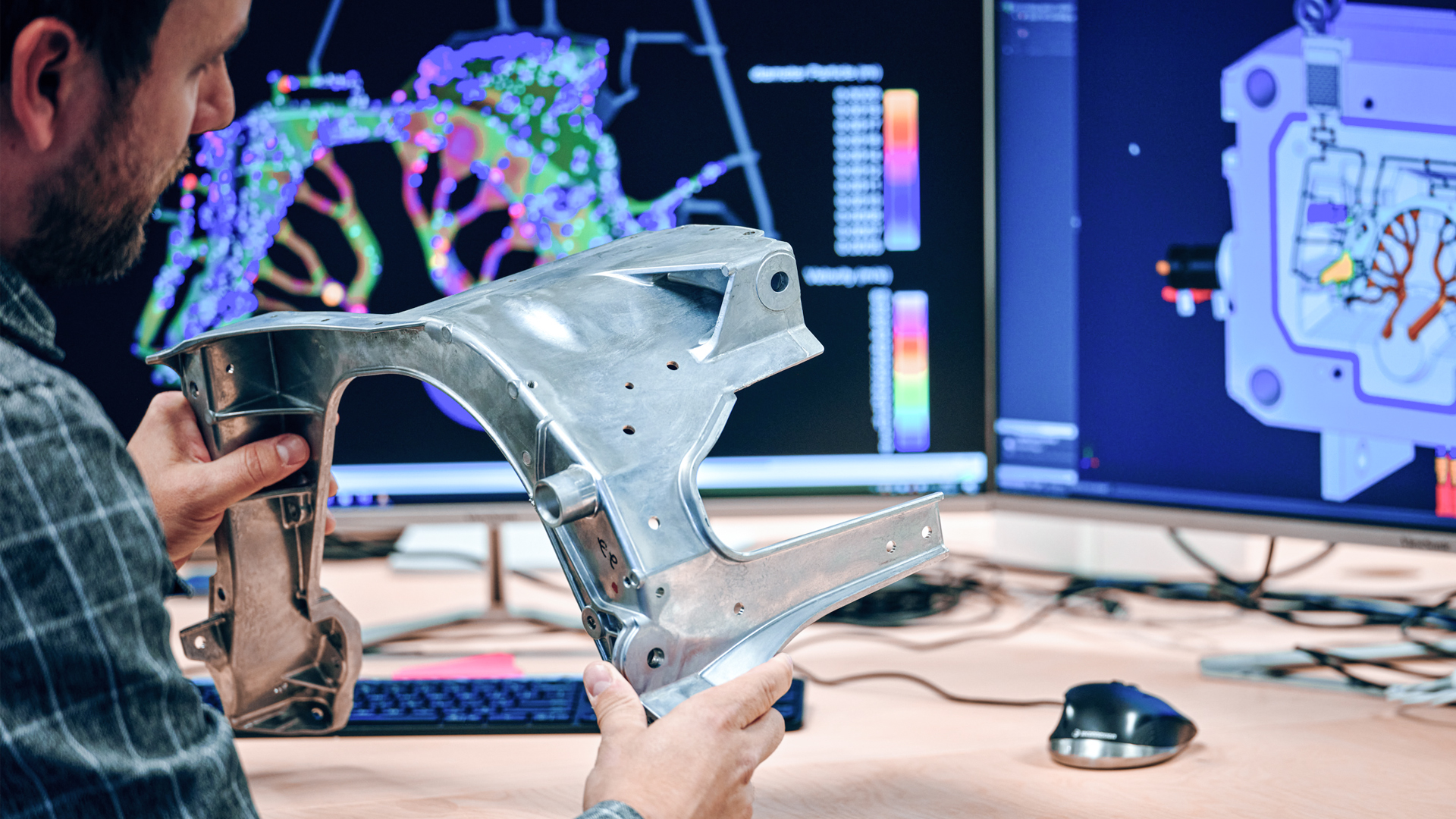

Engineering validation (DFM-driven): load-path design for torsion/impact/fatigue; casting fill/solidification studies to optimize gating/venting/thermal balance; datum strategy aligned with machining needs.

Tooling

Fully designed and built in-house.

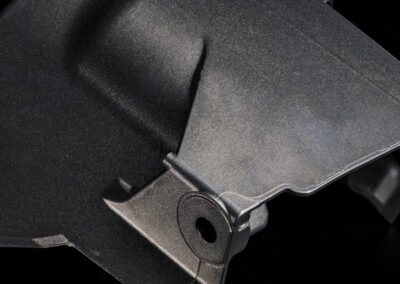

Sealed tool (vacuum-tight design)

Central injection design, 3 plate tool.

Dual ejection system to extract part from fixed tool side.

Tooling robustness for structural castings: controlled venting & vacuum pathways, thermal management features to stabilize dimensions, and maintainability considerations built into the die architecture.

AMT has developed the A+ process, created by the synergy of advanced technology, deep expertise and disciplined work methods that ensure a reliable supply of high-quality castings.

High-vacuum, below 50mbar in the cavity

Real time tool vacuum monitoring

Lubricant volume monitoring.

Controlled process window: shot profile & intensification discipline to reduce gas/porosity risk; melt quality practices (temperature discipline/cleanliness); cycle-to-cycle stability focus with documented records.

Quality evidence (as required): dimensional control via 3D metrology; internal soundness validation (X-ray/CT) and mechanical verification aligned to customer specifications.

AMT’s electric powered furnaces provide the lowest carbon footprint in the industry for your parts.

AMT reduces its customers’ carbon footprint: See How

_______

FIND OUT MORE | AMT Difference | AMT Expertise | AMT Engineering | AMT Tooling | Product Powersports |

_______